Services

An extensive range of facilities,

services and support

in unique, secure environments

Benchmarking

We create a common platform where all our customers will have

an access to the latest vehicles / product details

and BOM, weight, dimension etc.

So that individual companies need not invest

in buying their

competitor vehicle or products.

We create a common platform on virtual & physical product details where all our customer will have an access to identify the type of Benchmarking they required & our specialized below benchmarking approach give exact solution for there unique requirements.

1.Competitive Benchmarking

2.Functional Benchmarking

3.Product benchmarking

4.Performance Benchmarking

5.Diagnostic Benchmarking

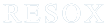

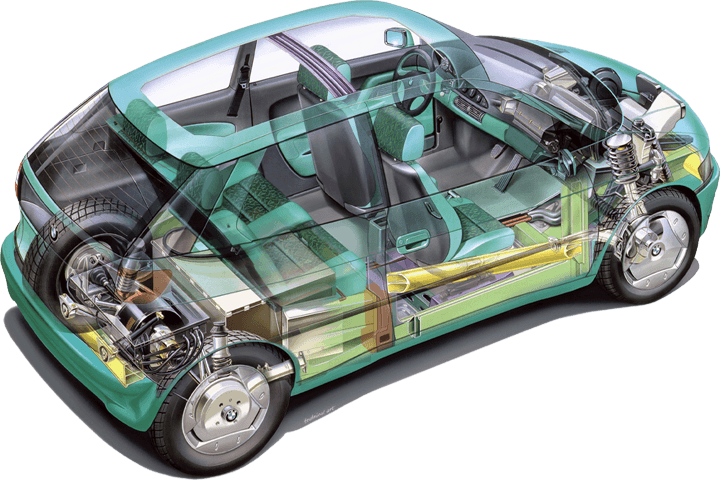

Virtual Teardown

Our next Gen vehicle Virtual Teardown methods extract & create the CAD data from entire vehicle to understand the design factors, assembly methods, integration & packaging approach..

We do both Traditional & virtual Teardown with our unique methodology for easy understanding of competitor components in depth view. By viewing virtual & physical engineering approaches helps to find the right information in most precised way.

We are working on creating the cloud platform for accessing the CAD information on request.

Our Specialties

We Can Do It All. Get In Touch For a Consultation

Automotive Benchmarking

Market Research

Full Vehicle Engineering

Should Costing

Prototype Validation

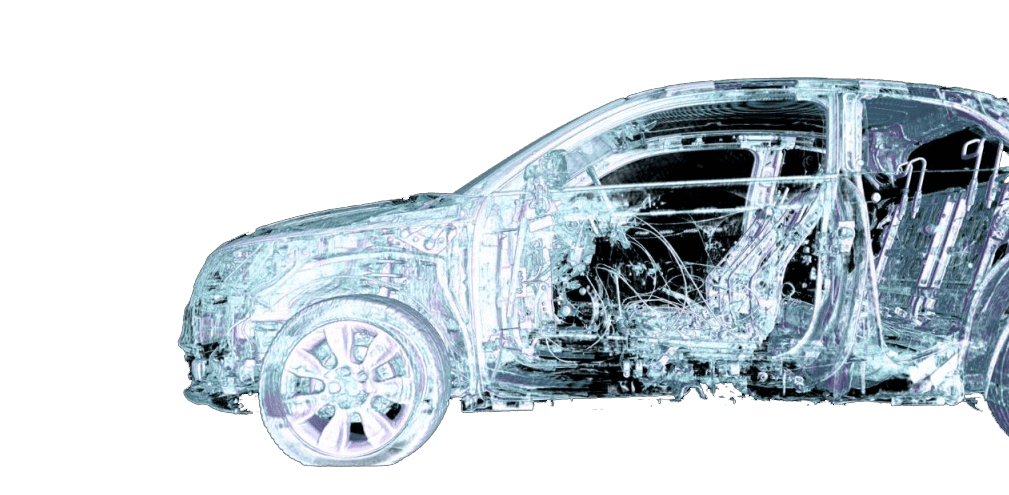

Virtual Prototype

We design & develop the high quality virtual and physical prototypes on benchmarking parts against customer requirement for understanding the concept’s function & commercial feasibility. Our prototype methodology will helps the initial ideas generation to the delivery of complete working products.

INNOVATE FASTER

REALIZE DESIGN ERROR SOONER

CUSOMIZE PRODUCTS

Resox offers all our customer a good chance to quick evaluate their unique benchmarking ideas by virtual prototyping concept models as that lead to understand the product design well either in integration,shapes,assembly & functionality as well as the appearance & styling.

HOW IT’S WORKS

Computer Aided Disign (CAD) creates a 3D Design Products

Final Design Converted to Electronic Design

Material become 3D Object

Printer Receives Electronic Files

Object is Automatically Dispensed

Product is Refined to Precise Shape

May be Refined using Traditional Secondary Operations

Virtual Validation

With our extract CAD data, we validate and compare the specific vehicle components & assemblies using CAE Tool to evaluate the performance, durability and optimization.

By the using of virtual prototyping and validation on benchmarking helps to predict products strength & weakness in depth way. It’s give our customer a wide range of design alternatives leads to improvements in performance and design quality and also the time required to bring the product to market is highly reduced.

Most importantly our customers can more easily find the idea and fix problems on the existing design that do not normally catch in the traditional benchmarking approach.

Copyright © 2018 Resox Automotive India Private Limited. All Rights Reserved.

Developed By Lassopic.com